CALL US TOLL FREE | 9am-6pm EST | M-F

LOCATIONS ACROSS THE NATION | TO SERVE THE ENTIRE COUNTRY

Leading Automotive Equipment Dealer Since 1987

CALL US TOLL FREE | 9am-6pm EST | M-F

LOCATIONS ACROSS THE NATION | TO SERVE THE ENTIRE COUNTRY

Leading Automotive Equipment Dealer Since 1987

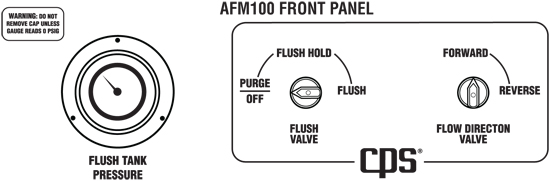

The AFM100 A/C Flusher machine is a valuable tool to any technician. Avoid repeat repairs due to system contamination. The purpose of flushing is to remove debris and contaminated oil, which renews and extends the life of the A/C system. This is done with only shop air and a good flushing solution. Comes with 8 foot hoses and universal couplers that will feet most connections, the 2-1/2 gallon capacity can do cars to buses. Most cars will only require 2 quarts where as a bus may need a full 2-1/2 gallons to reach all the hoses. There is a clear filter bowl for viewing of flushing solution to see what you are removing.

Flush Procedure

CPS Products, Inc. recommends flushing the A/C system any time the compressor is replaced or system contamination is suspected. This procedure is necessary to remove contaminants generated by a failed or worn compressor. A/C system contaminants are the major cause of replacement compressor failures. The preferred method of A/C system cleaning is the use of a closed loop flushing system. A flushing machine, such as the AFM100, is highly recommended for a more complete and thorough cleanup procedure. An alternate method of system cleaning is the use of a flush gun and shop air. This method does not move enough liquid flush to properly remove contaminants.

Individual Flushing

The condenser is the primary receptacle of compressor generated contamination. The condenser should be flushed in the REVERSE flow direction. Remove the inlet and outlet lines from the condenser. Introduce the flush chemical into the OUTLET (Liquid Side) of the condenser. Completely fill the condenser with flush chemicals. Allow the flush chemical to soak in the condenser for approximately ten (10) minutes. Remove the flush chemical by using filtered/dry shop air to blow the flush chemical out of the condenser through the INLET (Discharge Side). Repeat this procedure until all debris and lubricant is removed.

To clean the evaporator, remove the inlet and outlet lines, and thermal expansion valve (if applicable) or orifice tube. Follow the same procedure used with the condenser to ensure all debris and lubricant is removed.

Clean all hoses and lines for the A/C system in the same manner. You may flush the complete system in the same process without dismantaling if applicable.

* NOTES: NEVER FLUSH THE RECEIVER/DRIER OR ACCUMULATOR, COMPRESSOR OR THERMAL EXPANSION VALVE.

COMPONENTS SHOULD BE AIR PURGED TO REMOVE ALL REMAINING FLUSH CHEMICAL. CPS AFMSF FLUSH IS COMPATIBLE WITH ALL HFC134a LUBRICANTS, O-RINGS, ELASTOMERS, AND HOSE MATERIALS.

FLUSH FLUID AND VAPORS ARE MILDY FLAMMABLE; KEEP AWAY FROM HEAT, SPARKS, AND ELECTRICAL EQUIPMENT. NEVER EXPOSE FLUSH CHEMICALS TO AN OPEN FLAME.

DISPOSAL: INSURE THAT USED PRODUCT AND CONTAINERS ARE PROPERLY DISPOSED OF IN ACCORDANCE WITH ALL LOCAL, STATE AND FEDERAL REGULATIONS